THIS ITEM CONFORM WITH THE FOLLOWING NORMATIVES:

-EN 250:2000 EN 144-2

-EN 12021 BREATHABLE AIR

SURFACE USE ONLY

MAX WORKING PRESSURE: 300BAR

OXYGEN COMPATIBLE GREASE INCLUDED

WARNING: THE OXYGEN GREASE IS USED ONLY TO PROTECT THE ITEM FROM CONSEQUENCES OF IMPROPER USE.

REMEMBER: NEVER USE THE PERSONAL FILTER WITH PURE OXYGEN!

WARRANTY

Be carefully: THE PERSONAL FILTER is used to reduce the impurity of pressurized gases filled in case of impropriate maintenance of compressors’ filters. It is an additional filter. It doesn’t substitute the compressor filters.

The person who dismounts and reassembles the item is responsible for its proper functioning. Scubatec company manufactures PERSONAL FILTERS according to CE ISO 9001/2008 quality norm. Scubatec is free from responsibility for improper use of their products. We also remind you that all tanks used with PERSONAL FILTER should comply with the P.E.D. certification system.

INTRODUCTION

This manual is dedicated to professionals in the domain of maintenance and repair of diving equipment. It is not a manual for beginners!

Before carrying out any repairs Scubatec requires taking part in practical training followed by an exam and service technician certification.

This manual should be read carefully before carrying out any repairs.

Do not use the filter beyond the scope of its typical use.

Do not damage the internal threads.

Check the internal filter every 6 months.

IN ORDER TO ELIMINATE RISKS OF IMPROPER USE, PLEASE USE ONLY OXYGEN-COMPATIBLE GREASE.

Before making the maintenance Scubatec provided the course to assist the products.

Don’t use the filter in a different way from its tipical use. Do not use it as a hammer. Do not damage the thread. Verify every 6 mounths the alluminium filter inside.

SERIAL NUMBER

All Scubatec Personal Filters are marked with a serial number that identifies the production lot. It should be clearly visible on the external surface.

Should an accident occur due to a defect, promptly notify Scubatec indicating the serial number.

READY TO USE

The filter is ready to use with a DIN-threaded cylinder valves.

To assure proper functioning the Personal Filter must be screwed till the end of the valve’s thread. Verify the DIN connection o-ring. It should be free of ruptures and/or any residue.

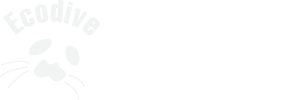

DISASSEMBLY

To disassemble the DIN adapter from the aluminum pipe it is necessary to tighten it in a vice with aluminum jaws in order to avoid damaging it. Unscrew the two final fittings counterclockwise.

PERIODIC MAINTENANCE

Periodic maintenance of the fittings is required in proportion to the use (at least ONCE A YEAR).

Proceed as follows:

– Disassemble, review and clean all components;

– Replace items no. 2,3N, 4N-6,7,9-11, as shown in the attachment using only original Scubatec spare parts;

– Make a visual check (check for any porosity of the material inside the tube);

– Reassemble as shown in the attachment using only oxygen compatible parts.

REVISIONS

Personal filters must undergo annual reviews at authorized service centers. The annual review involves checking, disassembling, cleaning, reassembling and functioning checks;

Weared and teared parts should be replaced.

SPARE PARTS

It is necessary to replace all viton o-rings listed in the attachment.

CLEANING

To clean all the metal parts, insert them into an ultrasound cleaning machine; in the absence it will be sufficient to immerse them in a hot detergent mixture, for example a solution of 50% water 50% white vinegar; rinse with low-limescale water.

To reassemble the components, grease the o-rings WITH the relevant SCUBATEC ORIGINAL OXYGEN COMPATIBLE GREASE.

CONTROL

Assembled personal filters need to undergo a material stress-tests in authorized retesting centers. The first test should be carried at least 4 years after registration and then every two years.

Relaterade produkter

Tillbehör regulatorer

Tillbehör regulatorer

Tillbehör regulatorer

Tillbehör regulatorer

Tillbehör regulatorer

Tillbehör regulatorer

Tillbehör regulatorer

Tillbehör regulatorer